IBR & ISO – 9001 – 2015 CERTIFIED

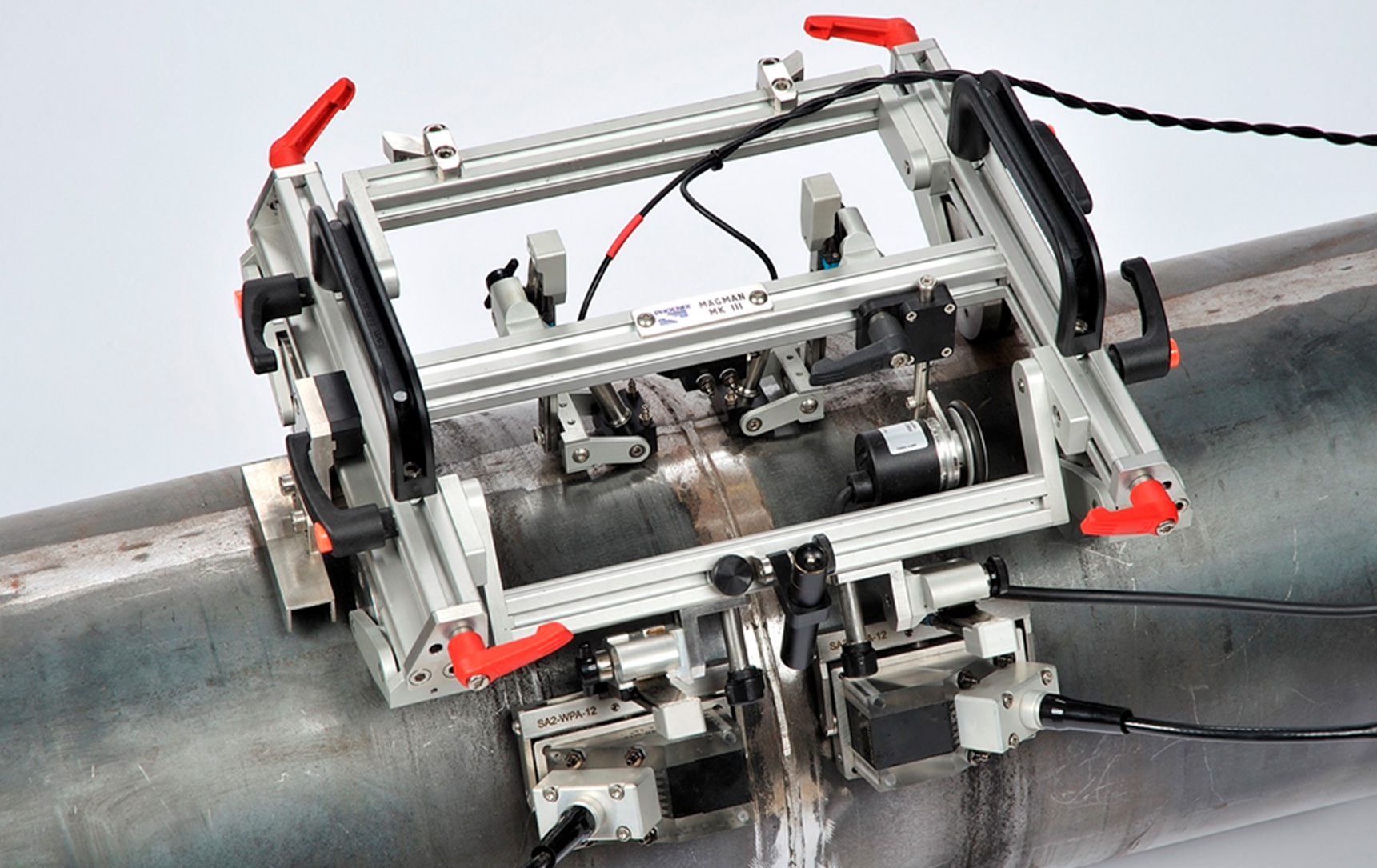

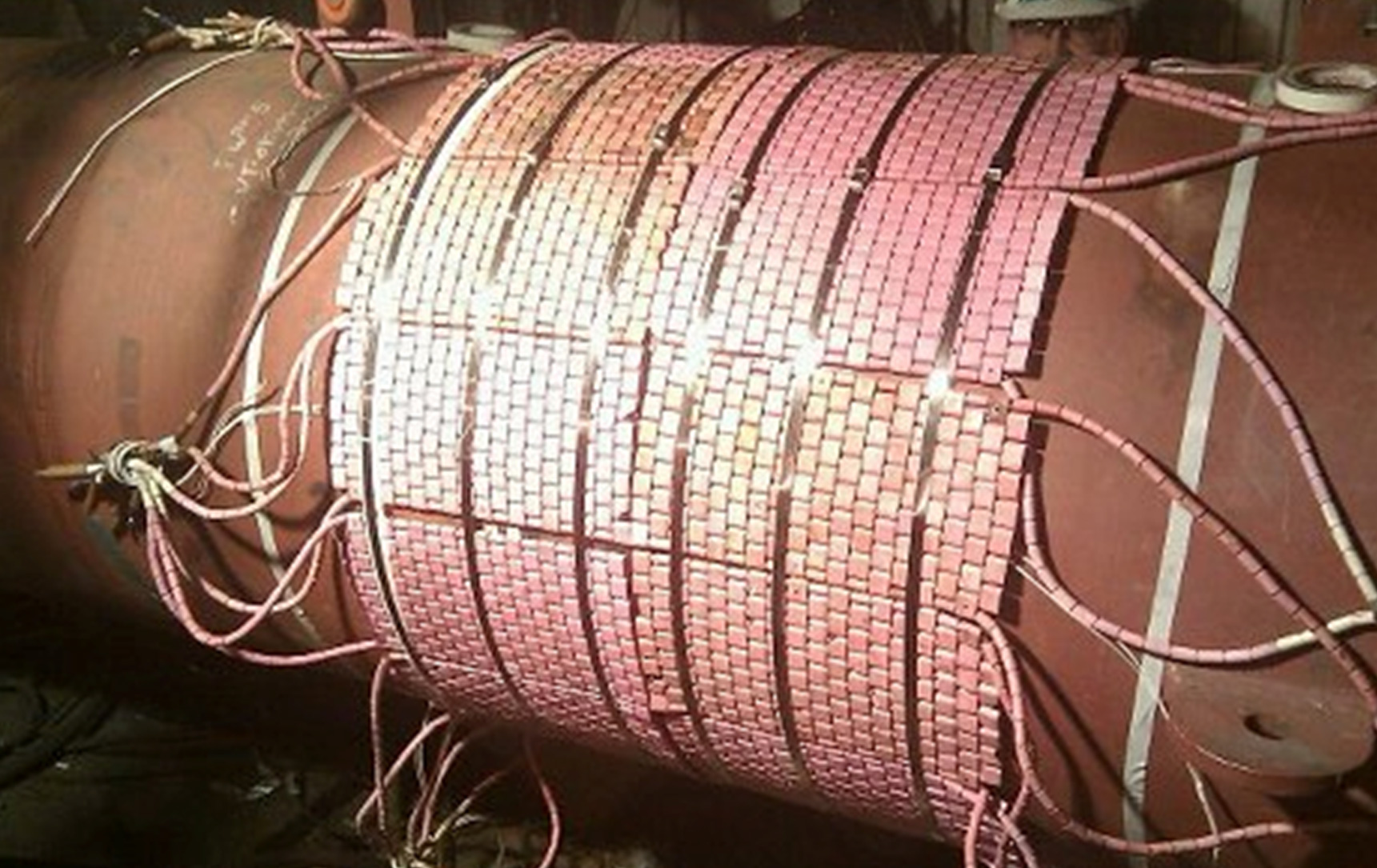

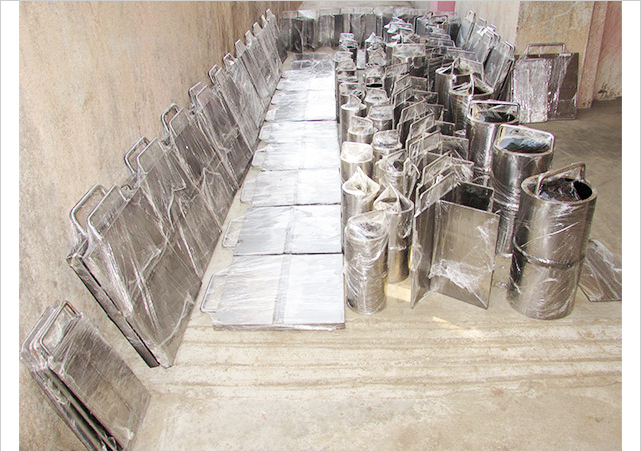

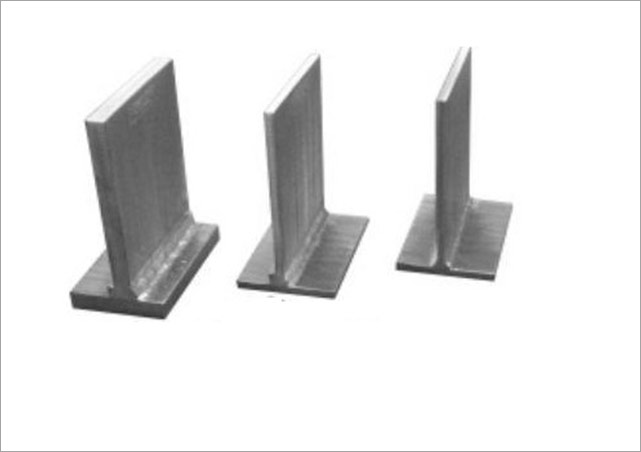

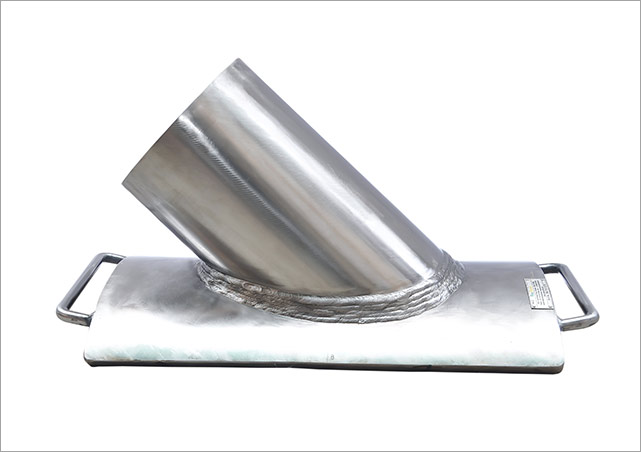

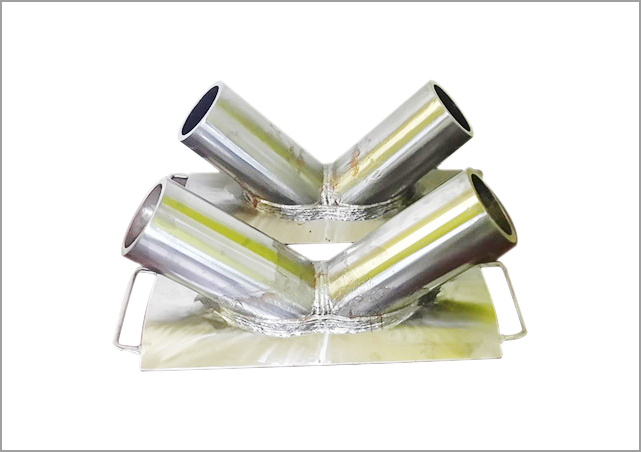

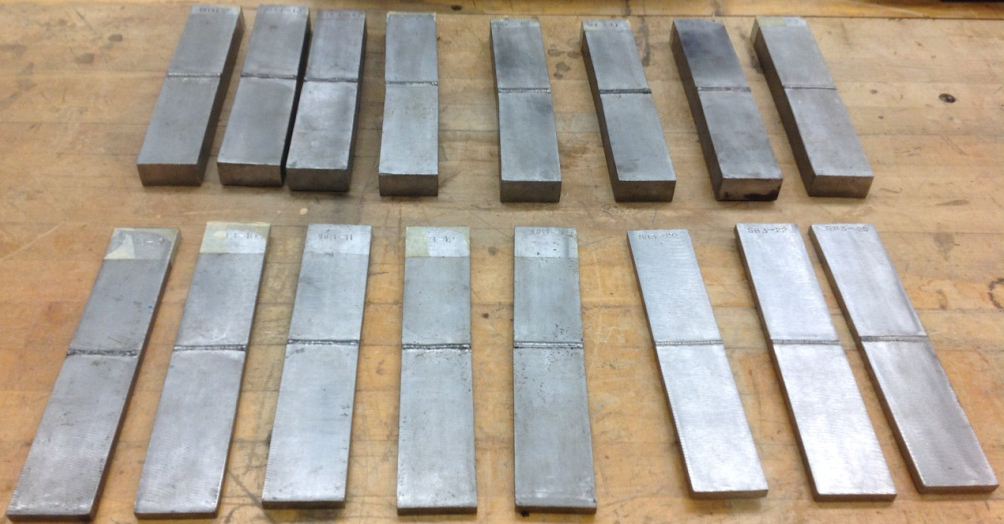

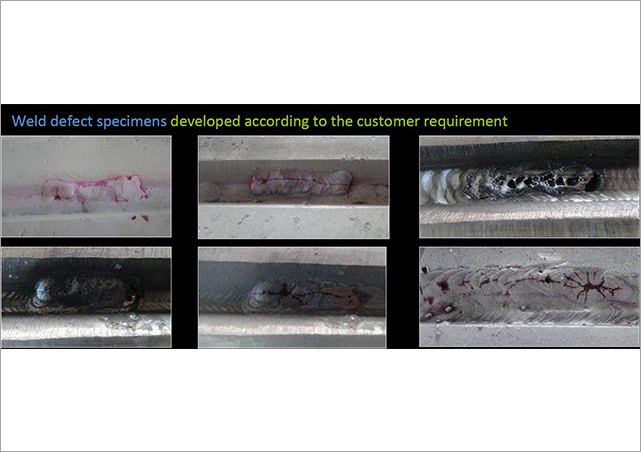

RAYSONIC NDT Services is a pioneer service provider since 2012 in oil and gas industries globally, providing Non-Destructive Testing, Heat Treatment and related services. We also manufacture NDT Flaw Implanted Specimens, various Heat Treatment Control panels and Furnaces.

All our services are carried out to meet the client requirements, specifications and standards by well-qualified personnel having vast experience in this technology. On Time Every Time service influenced by Safety